Paper Industry

Efficient Electric Process Heating for all Drying Processes in the Paper Manufacturing

Electrification of Process Heat

The decarbonization of the producing industry is essential for a successful energy transition and achieving climate goals.

Our Power-to-Heat plant uses a sophisticated technology to create an economically attractive alternative to fossil fuels as the main energy source for process heat. It is able to electrify processes that require temperatures up to 1.200°C (2.192°F) and reach the maximum capacity of high temperature energy storages.

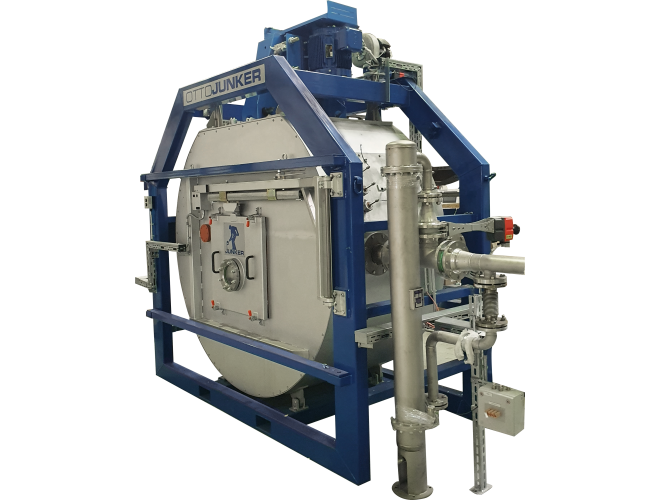

Deactivation of Lithium Batteries

The development of a functioning circular economy for Lithium Batteries is crucial due to the rising demand by e-mobility and the shortage of ressources. Damaged Batteries are highly flammable and difficult to extinguish.

With Otto Junker Solutions High Pressure Furnace we can eliminate that risk efficiently by removing the electrolyte under inert atmosphere. That enables a safe and efficient recyling process.

Pyrolysis of UBC, WEEE & Co.

A lot of everyday products are so called composites. The most popular are beverage cans, milk cartons and electronic components like printed circuit boards (PCB). These contain precious metals that are inseperable connected to other materials, mostly plastics. The only way to regain those metals is by pyrolysis.

The Rotary Kiln Furnace removes organic contents from those materials under inert atmosphere and uses their calorific value energy to deliver most of the process heat. The metals remain and can be melted efficiently.

Electrification of Aluminium Melting Furnaces

Aluminium is one of the most important materials of the future which makes an environmentally friendly production process essential for achieving climate goals and reducing CO2 emissions. Nowadays Aluminium is mostly melted in fossil fueled single- or double chambered melting furnaces which not only have advantages in cost but also in terms of operational qualities.

Together with Speira GmbH we invented and developed a system that is able to convert fossil fueled melting furnaces to inductively heated ones by maintaining the resulting material quality and the continuous operation.

You want to make a contribution to the energy transition?

We are constantly looking for new colleagues to strengthen our Team

Paper Industry

Efficient Electric Process Heating for all Drying Processes in the Paper Manufacturing

learn more

learn more Food Industry

Electrification of all Thermal Oil, Steam, Hot Water and Hot Air Applications in the Food and Beverage Production

learn more

learn more Wood Industry

Net-Zero Process Heat for the Production of Sustainable Wood Materials

learn more

learn more Chemical Industry

1.200°C Process Heat from Renewable Sources. Applicable from Distillation to Steam Cracking

learn more

learn more Battery Industry

Thermal Recycling Technologies for a Safer and more Efficient Recycling Process of Lithium Batteries

learn more

learn more Metal Industry

Electrification of the Aluminium Recycling Route and Electrification of Aluminium Melting Furnaces

learn more

learn more Get in touch with us