Power-to-Heat

For a successful energy transition in the producing industry it is necessary to switch from fossil fuels to climate neutral energy sources. The biggest obstacles here are economically attractive and sophisticated technologies that produce clean process heat.

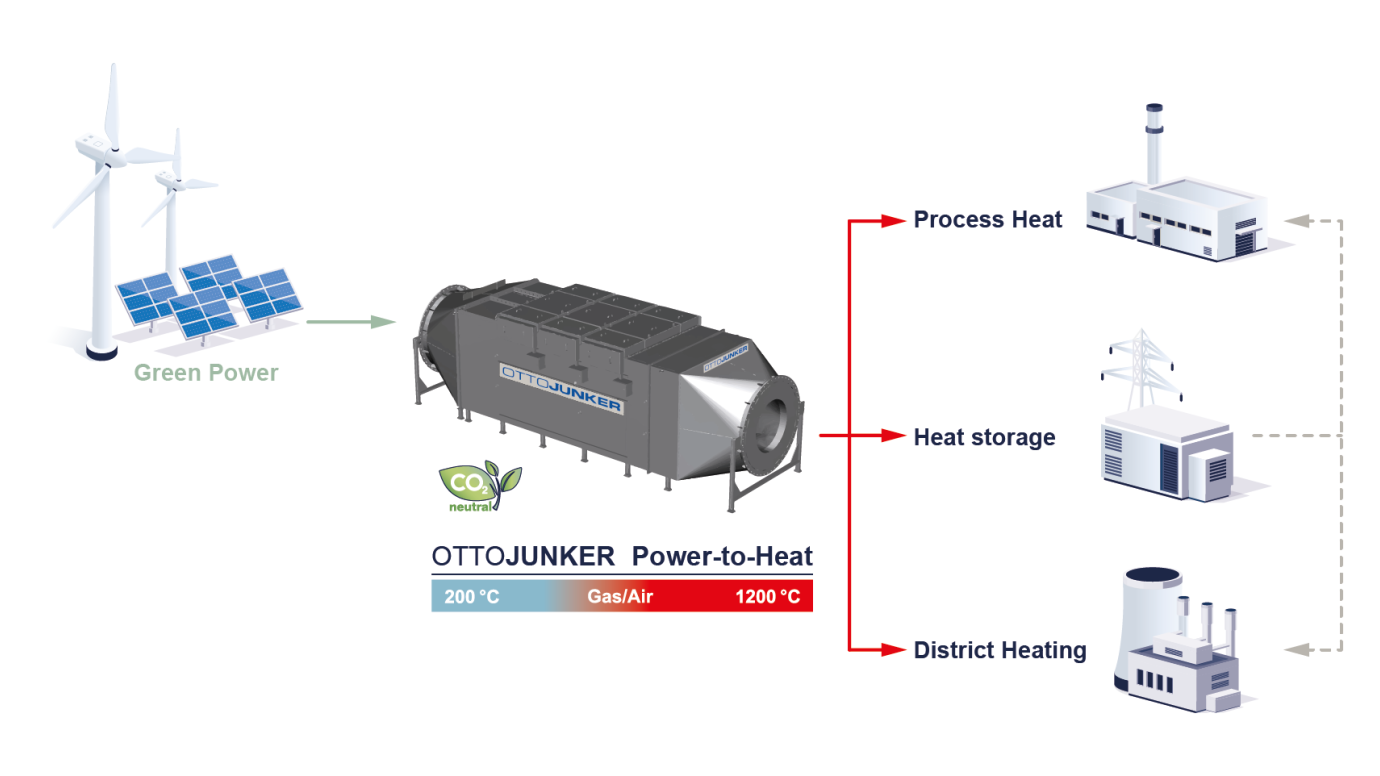

Otto Junker Solutions developed a Power-to-Heat plant that produces the required heat demand which can be used for all kinds of industrial processes. By using electrical resistance heating the plant is able to heat air up to 1.200 °C (2.192 °F) with an efficiency of 98 %. A patented technology enables the use of heating wires close to their natural load limit by monitoring their exact temperature. This is crucial for the maximum temperatures and lifetime of the plant and increases the longevity.

Beside using the heated air directly in drying processes or the heating of metal for example, it can also be transferred on to thermal oil or be used to produce steam, which is essential for a wide variety of processes. The waste heat of those processes can be redirected back to the Power-to-Heat plant which will then be heated again and therefore ensuring a high energy efficiency and no wasted energy.

The plant operates on AC and DC voltages. It is easily scalable from 100 kW to 10 MW and has an energy density of around 800 kW/m3. The power is fully adjustable and the plant does not create repercussions on the power grid.

The plant was developed and tested by participating in the in the multiTESS project of the Solar-Institute-Jülich, which also researches the ability to be deployed as an energy storage that can regain the used electricity.

The combination of a Power-to-Heat plant and a high temperature heat storage provides further advantages than just being a climate friendly alternative to fossil fuels. The heat storage creates flexibility which allows the participation at the electricity wholesale market. That enables companies to take advantage of low or even negative electricity prices which makes heating with electricity economically attractive sooner.

In holding mode, which keeps the heating wires warm, the plant is able to react quickly to low electricity prices or provide transmission system operators with control energy to help balance the frequency of the electricity grid. Not only will that increase the lifespan of the heating wires but it will also save companies money and in the case of providing control energy generate further income.

- reduction in carbon emissions

by using green electricity

- lower energy cost

by using cheap electricity from the stock market

- applicable for therma oil, steam, hot water and hot air processes

due to heat exchanger

technical data

| Power | 0.1 - 10 MW |

|---|---|

| Power Density | 800 kW/m3 |

| Efficiency | 98 % |

| Gas Temperature Input | 20 - 800 °C (68 - 1,472 °F) |

| Gas Temperature Output | 200 - 1,200 °C (392 - 2,192 °F) |

| Gas Massflow | 0.1 - 20 kg/s |

| Voltage | 110 - 1,000 V |